By Travis Halsted, ARM, COSS, Loss Control Consultant

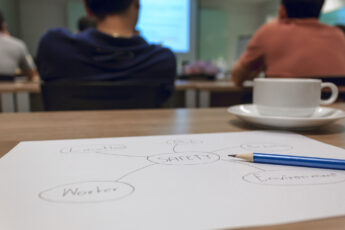

In the upcoming year of 2023, I will be celebrating my 10 year anniversary with MTMIC. I have met some amazing people and been through incredible facilities that complete processes that truly change the world. Regardless of the type of facility, I am often met with the question of “what else can we do”. That facility may have a strong safety culture within their employees, and a proactive management commitment to health and safety, but they still want to do more. I can answer them quickly and with certainty. I simply tell them to find the third leg of their triangle of success. With that answer I often get a unique look, but they are usually intrigued and want to hear more.

(more…)