By Travis Halsted, ARM, COSS, Loss Control Consultant

As the snow starts to build up, each of us would love to be thinking about the days where we will be turning on the air conditioning. The thoughts of doing our favorite activities in the sun seem to creep into our heads more, and more often. Those days will hopefully be here soon enough, and we should start to think about the preparation of the cooling fans that may be used in your work environment. These cooling fans include, but are not limited to: pedestal fans, box fans, pole mounted fans, industrial drum fans, and even the turbine air movers. With each of these fans there are infractions to be reviewed, and best practices to be considered. These fans are often moved from area to area, and due to this they can have particular items that are damaged, thus causing infractions.

Common Infractions

On any type of cooling fan there are some very common infractions that you can easily identify at a quick glance. Here are a few of those common infractions:

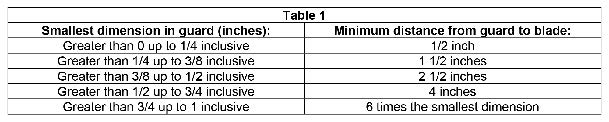

Fan Guarding – Possibly, the most common infraction that I find is fan guarding. As the fan vibrates, screws fall out, and guarding shakes loose. As guarding is bumped into, and fans are knocked over, the guarding may become damaged, and cause openings where they shouldn’t be. It is vital that fan guarding is inspected to ensure that the proper spacing is maintained. According to MIOSHA, the blades of a fan, located within 7 feet of a floor or working level, and used for ventilation or cooling of an employee, shall be guarded with a firmly affixed or secured guard. Any opening in the guard shall have not more than 1 of its dimensions more than 1 inch, and the distance to the blade shall not be less than that prescribed in Table 1.

Plug Ground Prong – In my experience, the majority of plugs that I find missing the ground prong are on the power cords for cooling fans. Employees will often pull on the cord to unplug the fan. As the ground prong is not molded into the plug, it will often become loose, and eventually fall out of the plug. This missing ground prong is not only an electrical hazard, but also something that MIOSHA will cite.

On/Off Switch – Fans are often turned on, and shut off by unplugging the power cord from the power supply. This is not only unsafe, but is also not compliant. Powered electrical equipment is required to have on/ off switches. Fans can have different types of on/off mechanisms. The most common mechanisms are pull chains. These are often pulled out over time, and need to be replaced. Other mechanisms can be twist knobs on the motor, toggle switches on the motor, and inline switches found on the power cord. Each of these provide you with the ability to ensure that fans are turned on, and shut off via a switch versus the “hot plugging/unplugging” option.

Exposed Wiring – As the fan power cords often lay on the floor in work areas, there is a high likelihood that these cords are walked on, and items are placed on the cords. This can cause the insulation to break/tear, thus exposing the wiring inside. This is not only a high hazard exposure, but is also a Serious Violation from MIOSHA. Another location where wires can become exposed on the power cord is where the wires come out of the motor housing. Finally, wires can often become exposed at the plug as well. Inspecting these three locations on a single power cord can protect your employees from injuries, and your company from MIOSHA fines as well.

Best Practices

Movement of fans – Every year our claims department fields claims that involve injuries from employees that move cooling fans while the blades are spinning. Those blades should be guarded against accidental contact, but in some cases the guarding is not sufficient. When the employee moves the fan, the employee’s fingertips have been severely injured when they made contact with the spinning blades. Employees should be trained to shut off the fan, unplug the fan, and move it to the desired location before turning the fan back on. While this process seems remedial, it can prevent a severe injury to employees’ fingers.

Cleaning of fans – As your facilities all work with different atmospheric environments, a plethora of different types of particulates are circulating through the air, and through the blades of these cooling fans. As the air circulates through the fan there are buildups of the different particulates. This buildup could cause respiratory issues for your employees. The fan guarding, and blades should be set up on a cleaning schedule to remove the buildup of the particulates in your facility.

Audits – As I provided four of the most common infractions found on fans above, these items should be audited at intervals that work for your company. These audits should be aimed at the four items above, but also at the cleaning as well. From inspecting the cleanliness of the fans while auditing them, you may find a particular location in your facility that could use some air quality monitoring, and engineering controls.

While most of these items may be considered an “other than serious” violation, most fans that I find discrepancies on have a few, if not all, of the infractions listed above. This could result in $300 to $480 in fines, for something that could easily be remedied. I look forward to seeing you all during my upcoming visits, and I hope that our dreams of warmer weather come to fruition soon.