By Travis, Loss Control Consultant

Through every loss control visit, one particular hazard can be found in each facility. The hazard that I am speaking of is electricity. With each cord, disconnect, panel, receptacle and connection there are a plethora of hazards that must be guarded. Each of these electrical items have rules that pertain to them and failure to abide by these rules can not only provide the opportunity for severe injuries and possibly fatalities, but also the potential for substantial fines from the MIOSHA enforcement division. During a recent MIOSHA training class, the speakers informed the class that any and all electrical infractions will now hold a minimum $5,000 fine. That is only a minimum, as if they feel that the particular infraction is negligent then the fine will only escalate from there. While the fines are an eye opening factor, the safety of the employees should always remain as our top priority.

Since 2010, MTMIC has an incurred sum of just over $100,000 spent on electrical shock claims. While 85% of those claims are from direct contact with electrical current, the other 15% includes injuries from an object being lifted and pushed/pulled into an electrical current. These injuries have happened in foundries, fabrication facilities, plastic injection facilities and machine shops to name a few. While some industries may deal with electrical current and working with live equipment more than others, the potential for electrical shock is a possibility in any facility. It is paramount that we spend some time looking at the particular items that are common everyday violations.

Temporary Wiring

Some of the most common violations have to do with extension cords. As extension cords are a part of almost any facilities daily usage, it is paramount to understand what are the dos and don’ts of extension cords. For a true understanding of how MIOSHA looks at extension cords, it is important to know that they refer to extension cords as “temporary wiring”. For the sake of getting you to use the terminology that MIOSHA uses, I will refer to extension cords as such. Some of the most cited temporary wiring rules are:

1910.305(a)(2)(i) – Temporary electrical power and lighting installations of 600 volts, nominal, or less may be used only as follows;

1910.305(a)(2)(i)(A) – during and for remodeling, maintenance, or repair of buildings, structures, or equipment and similar activities.

1910.305(a)(2)(i)(B) – For a period not to exceed 90 days for Christmas decorative lighting, carnivals, and similar purposes; or

1910.305(a)(2)(i)(C) – For experimental or development work and during emergencies

While this temporary wiring is allowed under these rules, it MUST be removed immediately upon completion of the project or purpose for which the wiring was being used.

Another aspect to the temporary wiring citations would be under rule 1910.305(g)(2)(ii). This rule states that flexible cords may only be used in continuous lengths without splice or tap. This is saying that the flexible cords shall be used in a manner free of splices, even if in an approved electrical box. Along with this is the rule that electrical tape and shrink tubing are not sufficient forms to repair the temporary wiring or flexible cords. There is no approved method to repair a cord. The only item that MIOSHA has recognized to me, is cutting the cord (after it has been removed from any power supply) and installing a new plug just before the damaged section. The damaged section would then be discarded.

Labeling of Panels/Disconnects/Breakers, etc.

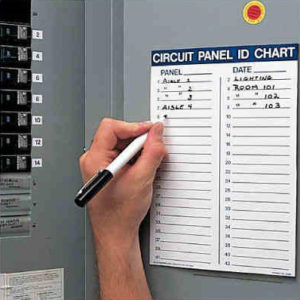

Rule 1727 (1) states that each switch, circuit breaker, and disconnector shall meet all of the following requirements: (a) be marked to indicate its purpose unless it is so located that the purpose is evident and it is secured against displacement and (b) be of the waterproof type where damp or wet conditions exist. This common violation pertains to the labeling of electrical control devices as to the item(s) that they power. For instance, when you open your electrical panel, there should be a key that dictates what each breaker or fuse powers. If there is a breaker or fuse that is not labeled, then that would be a violation. Even if the fuse or breaker is unused, it should be marked as such. This also goes for buss boxes and disconnects. These items have to be labeled as to the particular item(s) that they power. Furthermore, the labeling should be done in a manner that is legible and will not easily fade. The use of pencil is not recommended as pencil will fade quickly. Permanent marker and labels are what MIOSHA recognized as more of what they were looking for.

Rule 1727 (1) states that each switch, circuit breaker, and disconnector shall meet all of the following requirements: (a) be marked to indicate its purpose unless it is so located that the purpose is evident and it is secured against displacement and (b) be of the waterproof type where damp or wet conditions exist. This common violation pertains to the labeling of electrical control devices as to the item(s) that they power. For instance, when you open your electrical panel, there should be a key that dictates what each breaker or fuse powers. If there is a breaker or fuse that is not labeled, then that would be a violation. Even if the fuse or breaker is unused, it should be marked as such. This also goes for buss boxes and disconnects. These items have to be labeled as to the particular item(s) that they power. Furthermore, the labeling should be done in a manner that is legible and will not easily fade. The use of pencil is not recommended as pencil will fade quickly. Permanent marker and labels are what MIOSHA recognized as more of what they were looking for.

Breaker Panel Openings and Open Control Enclosures

1910.303(g)(2)(i) states that except as elsewhere required or permitted by this standard, live parts of electric equipment operating at 50 volts or more shall be guarded against accidental contact. Where the issue is often seen with this rule is when an electrical enclosure, such as a machine control box, has a door left open to help it remain cool. The door being open provides an exposure to the electrical current in the enclosure that an untrained employee could become seriously injured by. Furthermore, one particular item that I have been seeing more of during my inspections are electrical panels that are missing breakers and do not have a blank installed. This opening in the panel provides a potential and probable hazard to any employee that may be accessing that panel.

1910.303(g)(2)(i) states that except as elsewhere required or permitted by this standard, live parts of electric equipment operating at 50 volts or more shall be guarded against accidental contact. Where the issue is often seen with this rule is when an electrical enclosure, such as a machine control box, has a door left open to help it remain cool. The door being open provides an exposure to the electrical current in the enclosure that an untrained employee could become seriously injured by. Furthermore, one particular item that I have been seeing more of during my inspections are electrical panels that are missing breakers and do not have a blank installed. This opening in the panel provides a potential and probable hazard to any employee that may be accessing that panel.

Safety While Working Around Electricity

This section could result in page after page of possible safety items. From insulated tools, to proper safe distance measurements, to ensuring that there is no more than a certain measurement of dust within your enclosures, the discussion can be endless. While I would love to sit down and talk about electrical safety with you, I only have a short time with you in this article. With that being said, I will make you aware of one of the most cited items in regards to working within an enclosure. Rule 4006 (4) states that conductive articles of jewelry and clothing, such as any of the following shall not be worn if they might contact exposed energized parts unless rendered nonconductive by covering, wrapping, or other insulating means; watchbands, bracelets, rings, key chains, necklaces, metalized aprons, cloth with conductive thread and metal headgear to name a few. It should be best practices to never work with energized parts, but MIOSHA does recognize certain times in which it is okay to do so, thus it opens the possibility of having this infraction.

This section could result in page after page of possible safety items. From insulated tools, to proper safe distance measurements, to ensuring that there is no more than a certain measurement of dust within your enclosures, the discussion can be endless. While I would love to sit down and talk about electrical safety with you, I only have a short time with you in this article. With that being said, I will make you aware of one of the most cited items in regards to working within an enclosure. Rule 4006 (4) states that conductive articles of jewelry and clothing, such as any of the following shall not be worn if they might contact exposed energized parts unless rendered nonconductive by covering, wrapping, or other insulating means; watchbands, bracelets, rings, key chains, necklaces, metalized aprons, cloth with conductive thread and metal headgear to name a few. It should be best practices to never work with energized parts, but MIOSHA does recognize certain times in which it is okay to do so, thus it opens the possibility of having this infraction.

In an attempt to ensure that you are able to provide a thorough self-inspection of your facility, I feel it is prudent and essential that I give you a final quick snapshot of other items to look for. While walking through your facility look for the following items:

- Any kind of box (junction, receptacle, etc.) that does not have a cover.

- Damaged cords that may have the insulation worn away, thus exposing the green/white/black wires within the cord.

- Any missing knockouts on any electrical box of any kind.

- Wiring that is exposed at a plug at the wall. Sometimes the insulation pulls away from the plug over time, thus exposing some wiring at the plug

- Check your air movement fans to ensure that the wiring has not come out of the fan motor. We often see the wiring insulation slip out of the grommet on the fan motor and expose the wiring.

- Check ground prongs on all of your cords. Ground prongs are not molded into the plug and often come out of the plug.

- Ensure that you are keeping up with your lockout/tagout training. This is a vital aspect to a workplace that works safely with electricity.

Remember that each of these items not only provide a serious hazard to your employees, but are now all considered a serious infraction by MIOSHA with a $5,000 fine to start. This is only the tip of the iceberg on electrical items to look for in your facility. I strongly encourage you to contact your Loss Control Consultant to discuss any further electrical item questions and/or concerns. I hope you are all having a safe and productive 2018.